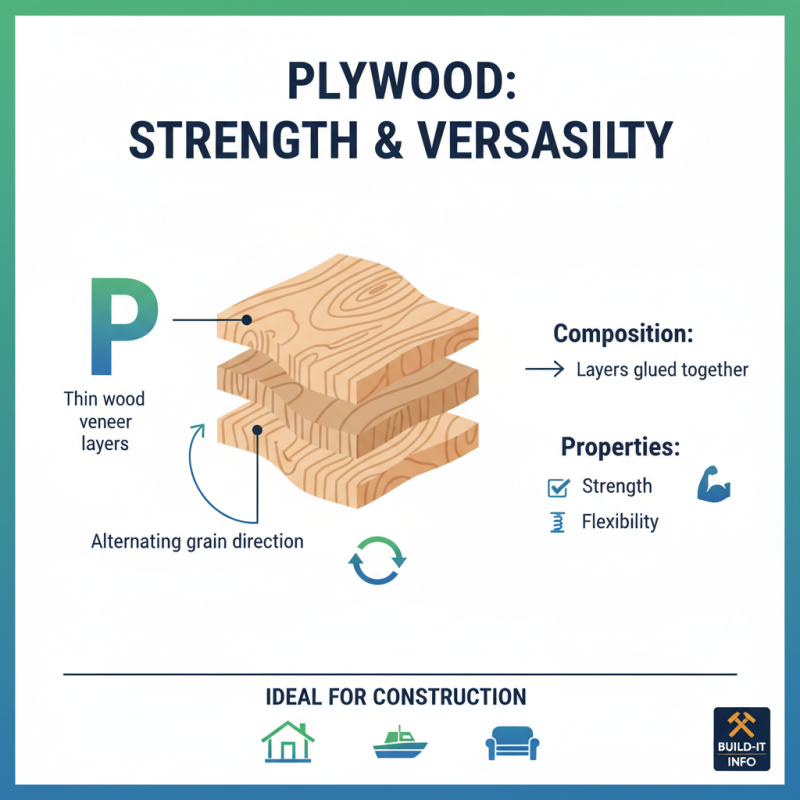

Plywood is a versatile building material widely used in construction. It consists of thin layers or "plies" of wood veneer, glued together. Each layer is oriented in different directions, providing strength and stability. The unique structure of plywood makes it resistant to warping and cracking, which is essential for various applications.

In construction, plywood serves multiple purposes. It is used for flooring, walls, and roofs, providing a reliable base for many projects. Builders often choose plywood for its lightweight nature and ease of handling. However, not all plywood is created equal. The quality can vary significantly, leading to potential drawbacks in certain situations.

While plywood is popular, it is not perfect. Some types may not withstand extreme weather conditions. Additionally, improper installation can compromise its structural integrity. It is crucial to choose the right type of plywood for the specific job and ensure it is installed correctly. Understanding the strengths and weaknesses of plywood can greatly impact construction outcomes.

Plywood is a versatile building material made by gluing together thin layers of wood veneer. Each layer, known as a ply, is oriented in alternating directions. This unique composition gives plywood strength and flexibility, making it ideal for various construction applications.

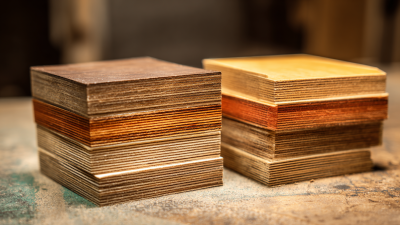

Plywood comes in different grades, with each grade serving specific purposes. Higher grades are smooth and visually appealing, while lower grades may have knots or defects. These imperfections can sometimes affect durability, so it's essential to choose the right grade for your project.

Tips: When selecting plywood, consider its intended use. For example, exterior applications require water-resistant options. Always check for certifications that indicate quality and safety.

Understanding plywood grade is crucial. The right choice prevents issues later. A mismatch can lead to structural failure or additional costs. It’s wise to consult a professional when uncertain about your selection.

Plywood has a rich history that dates back thousands of years. Ancient Egyptians used wooden planks glued together for furniture and decorative items. By the 19th century, modern plywood began to take shape. The development of adhesives and manufacturing techniques transformed its production. This innovation made plywood stronger and more versatile.

Today, the applications of plywood are vast. Architects and builders appreciate its lightweight nature. It’s commonly used in flooring, walls, and furniture. However, some find it challenging to work with. Cutting and finishing require precision. A poor cut can lead to wasted materials. Additionally, not all plywood is created equal. There are various types, and choosing the right one can be overwhelming.

The rise of sustainability has influenced plywood’s use. Many opt for eco-friendly options made from recycled materials. This choice reflects a growing awareness of environmental concerns. Yet, availability can be an issue in some regions. The quest for high-quality, sustainable plywood continues. There’s still debate over the best practices in sourcing and manufacturing.

Plywood is a versatile material used extensively in construction. Different types of plywood suit various applications, making it essential to know your options. One common type is structural plywood. It's made for heavy-duty tasks like flooring and roofing. Structural plywood has high strength ratings, ensuring it can support loads effectively.

Another variety is marine plywood. This type is resistant to moisture and used in boat construction. Its durability makes it ideal for projects exposed to water. According to industry reports, the marine plywood market is expected to grow steadily due to rising demand in the shipping industry.

When choosing plywood, consider the environment. Tips: Always check the source of your plywood. Sustainable options are available. Consider using formaldehyde-free products. They are better for indoor air quality. Remember, not all plywood is created equal. Mismatched applications may lead to issues down the line. Always ask for professional guidance to avoid missteps in your construction projects.

Plywood is an engineered wood product made from multiple thin layers. These layers, or veneers, are glued together with their grains alternating. This design creates a strong and stable material. It is widely used in construction for various applications.

One of the main benefits of plywood is its strength. The cross-laminated structure provides excellent resistance to splitting, cracking, and warping. This makes it suitable for floors, walls, and roofs.

Versatility is another key advantage. Plywood comes in different grades and thicknesses, allowing builders to choose what fits their projects best. However, care must be taken when selecting the right type. Not all plywood is created equal. The wrong grade can lead to problems down the line.

Plywood is also lightweight, making handling easier on job sites. Yet, it can absorb moisture if not properly sealed. This is a drawback that requires attention. Regular maintenance can help extend its lifespan.

Craftsmen often appreciate the ease of cutting and shaping plywood. But, precision is crucial; mistakes can waste valuable materials. It's important to consider both the benefits and the challenges of using plywood in construction.

Plywood is a versatile material widely used in construction. Its layered structure provides strength and durability. Common applications include walls, floors, and roofing. In residential buildings, plywood often serves as sheathing for walls. This helps with insulation and stability. It's a budget-friendly option that doesn't compromise quality.

For flooring, plywood can support various finishes, such as tile or carpet. It offers a smooth surface that can withstand wear and tear. Many builders appreciate its lightweight nature, making transportation easier.

Tips: Always check for the right grade of plywood for your project. Higher grades offer better finish quality but can be costlier. Consider using eco-friendly plywood options when possible.

Walls made from plywood can be finished in many ways. Paint, wallpaper, or wood stains all work well. However, some might not consider how moisture affects plywood. In humid areas, using treated plywood is crucial to prevent warping.

Tips: If you are unsure about installation, consult a professional. They can guide you to make the right choices for your space.

Signup our newsletter to get update information, promotion or insight.