When embarking on a woodworking project, one of the most critical decisions you'll make is selecting the right plywood board. Plywood is a versatile material that serves countless applications, from furniture making to construction. However, with a myriad of options available, determining which type of plywood board best suits your needs can be daunting. The choice of plywood can significantly affect the durability, appearance, and overall success of your project.

In this guide, we will explore ten essential tips to help you navigate the selection process. Understanding the various grades, finishes, and types of plywood available is crucial in ensuring that you choose a board that not only meets your aesthetic desires but also provides the necessary strength and stability for your specific use. Whether you are a seasoned woodworker or a novice enthusiast, these tips will empower you to make informed decisions, ultimately enhancing the quality of your work and the longevity of your projects. Let's delve into the key factors you should consider when choosing the perfect plywood board for your next endeavor.

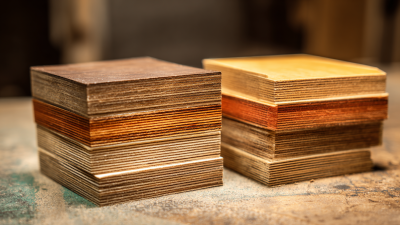

When selecting the right plywood board for your projects, understanding the different types of plywood and their uses is crucial. Plywood typically comes in several varieties, each tailored for specific applications. For instance, veneer plywood is ideal for furniture and cabinetry due to its aesthetic appeal, while marine plywood, designed to withstand moisture, is perfect for boat construction and outdoor furniture. Knowing these distinctions helps ensure your project’s durability and visual integrity.

One essential tip is to consider the thickness of the plywood. Thicker plywood provides better strength and stability, making it suitable for flooring and structural applications. In contrast, thinner sheets are more appropriate for projects where flexibility and weight matter, like crafting or wall paneling. Additionally, always check the grade of the plywood; higher grades indicate fewer defects, which is vital for high-quality finish work.

Lastly, don't overlook the importance of sourcing your plywood from reputable suppliers. This not only guarantees the quality of the material but also provides insights into its intended uses. A knowledgeable supplier can assist you in finding the right type for your specific needs, ensuring the success of your project.

When selecting plywood for your projects, it is crucial to evaluate its quality based on several key characteristics. First and foremost, consider the grade of the plywood. Higher grades, such as A or B, indicate a smoother surface with fewer defects, making them ideal for visible applications. Conversely, lower grades may contain knots, splits, or other imperfections that could compromise the integrity of your project. Understanding these grades will help you choose the right plywood based on aesthetic and structural needs.

Another significant factor to assess is the core material and its composition. Plywood can have different core types, including solid wood, particleboard, or MDF, each influencing strength and durability. Plywood featuring a solid wood core is typically more robust and resistant to warping, making it suitable for heavy-duty applications. Additionally, the number of veneer layers, or plies, also plays a role; more layers often equate to a stronger board. Lastly, pay close attention to the adhesive used in the plywood; exterior-grade adhesives are crucial for water resistance, particularly in areas subjected to moisture. These characteristics combined will ensure you choose a high-quality plywood that meets your project’s demands.

When choosing the right thickness of plywood for your project, it's crucial to consider the intended use and the specific requirements of your build. The thickness of plywood can significantly affect the strength, durability, and overall performance of your crafted items. Generally, thicker plywood boards offer greater strength and are ideal for heavy-duty applications, while thinner boards can be perfect for lightweight projects or decorative purposes.

Tip 1: For structural applications, such as flooring or roofing, opt for plywood that is at least 3/4 inch thick. This thickness provides the necessary support and weight-bearing capability, ensuring safety and stability in your construction.

Tip 2: If your project involves creating furniture or cabinetry, consider using 1/2 inch plywood. This thickness balances strength and weight, making it suitable for many projects without being overly cumbersome.

Finally, always keep in mind the environmental conditions where the plywood will be used. If your project is exposed to moisture, select plywood that is formulated for wet conditions, which may also influence the thickness needed for optimal performance.

| Tip Number | Tip Description | Recommended Thickness | Common Uses |

|---|---|---|---|

| 1 | Determine the specific requirements of your project. | 3/4 inch | Furniture, cabinetry |

| 2 | Assess the load-bearing capacity needed. | 1/2 inch | Shelving, wall panels |

| 3 | Consider the location and environment of use. | 3/8 inch | Interior projects |

| 4 | Evaluate potential exposure to moisture. | 5/8 inch | Subfloors, outdoor projects |

| 5 | Consult plywood grade and type based on purpose. | 1/4 inch | Back panels, craft projects |

When embarking on a project that requires plywood, considering eco-friendly options is essential for promoting sustainability in construction. Eco-friendly plywood is typically made from sustainably sourced wood, which ensures that forests are not overexploited and biodiversity is preserved. Additionally, selecting products certified by organizations such as the Forest Stewardship Council (FSC) guarantees that the plywood comes from responsibly managed forests, making it a more sustainable choice for environmentally conscious builders.

Another important aspect to consider is the choice of adhesives used in the plywood. Traditional plywood can contain harmful chemicals that may off-gas volatile organic compounds (VOCs), which are detrimental to indoor air quality. Opting for zero-VOC adhesives minimizes environmental impact and creates a healthier living space. Furthermore, some manufacturers offer alternatives like bamboo plywood or reclaimed wood options, which not only reduce demand for new timber but also contribute to a circular economy. By prioritizing eco-friendly plywood, builders can help create structures that are not only durable but also kind to the planet.

When it comes to working with plywood, accuracy in measuring and cutting is crucial to achieve the best results in your projects. According to the APA - The Engineered Wood Association, proper cutting techniques can improve the strength and durability of your finished work by up to 30%. Therefore, investing time in measuring accurately is key. Start by using a high-quality measuring tape and a straight edge to mark your cuts. A circular saw is often the best tool for these tasks, but make sure it has a fine-tooth blade to minimize tear-out and splintering.

Another important tip is to always cut on the waste side of your markings. This approach ensures that small inaccuracies in your cuts won’t affect the final dimensions of your board. Additionally, using clamps can stabilize the plywood, which not only enhances safety but also allows for more precise cuts. The Woodworkers Guild of America recommends making a few test cuts on scrap pieces before starting your actual project, as this can provide invaluable experience and help you refine your technique. By adhering to these simple yet effective tips, you can significantly elevate the quality of your woodworking endeavors.

Signup our newsletter to get update information, promotion or insight.