When embarking on any woodworking project, selecting the right materials is crucial to achieving the desired results. Among the various materials available, finished plywood stands out due to its versatility, durability, and aesthetic appeal. With numerous options on the market, however, choosing the best finished plywood for your specific project can be a daunting task. This guide aims to simplify that process by presenting essential tips that will equip you with the knowledge needed to make informed decisions.

Understanding the characteristics of finished plywood is the first step in your selection process. From construction quality to finish types, the choices you make will directly impact not only the functionality but also the visual appeal of your project. Whether you're crafting furniture, cabinetry, or decorative pieces, knowing what to look for in finished plywood can enhance your project's overall effectiveness while adding a polished touch. In this article, we will delve into ten key tips that will ensure you choose the best finished plywood, tailored to meet your unique needs and preferences.

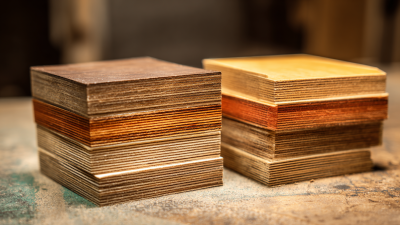

When it comes to selecting the ideal finished plywood for your projects, understanding the various types and grades of plywood is crucial. Plywood is typically categorized into three main types: softwood, hardwood, and engineered plywood. According to the American Plywood Association, softwood plywood is commonly used in construction and furniture-making due to its cost-effectiveness and strength. Hardwood plywood, on the other hand, is favored for its aesthetic appeal and durability, making it ideal for high-end cabinetry and fine furniture. Engineered plywood, such as laminated veneer lumber (LVL), is utilized in applications requiring enhanced structural integrity, often preferred in heavy construction.

Grades of plywood also play a vital role in determining its suitability for specific projects. The grading system ranges from A to D, with “A” representing the highest quality, featuring a smooth, defect-free surface suitable for visible applications, while “D” exhibits more imperfections, making it suitable for hidden structural components. As noted in a recent report by Market Research Future, the demand for high-grade plywood is anticipated to increase by over 5% annually through 2025, driven by the growing construction industry and rising interest in sustainable building materials. Choosing the right type and grade of plywood not only impacts the visual outcome of your project but also its longevity and structural reliability.

When selecting finished plywood for your projects, there are several key factors to consider that can greatly affect the outcome and durability of your work. First and foremost, assess the type of veneer on the plywood; high-quality veneers not only provide a more attractive finish but also contribute to the overall strength and stability of the material. Plywood with multiple thin layers tends to outperform those with fewer, thicker layers, as the cross-graining technique enhances resistance to warping and splitting.

Another essential tip is to evaluate the plywood’s grade and thickness. Higher-grade plywood will have fewer defects and provide a smoother surface, making it ideal for projects where aesthetics are a priority. Additionally, consider the intended use of the plywood; for heavy-duty applications, opting for thicker panels can offer better load-bearing capabilities. Finally, always examine the adhesive used in the plywood, as low-quality adhesives may compromise the integrity of the finished product, especially in humid conditions. By paying close attention to these factors, you can choose the best finished plywood tailored to your specific project needs.

When assessing the quality of finished plywood products, the first factor to consider is the grade of the plywood. Plywood is typically categorized into grades ranging from A to D, with A being the highest quality, featuring a smooth and blemish-free surface.

A higher grade usually indicates fewer repairs and defects, enhancing the overall appearance and usability for projects that require a polished finish. Checking for consistency in thickness across the sheets can also indicate quality, as inconsistencies may lead to structural weaknesses or finishing challenges.

Another crucial aspect of quality assessment is the bonding and adhesives used in the plywood. Opt for products that utilize high-quality, water-resistant adhesives, particularly if your projects involve exposure to moisture.

Additionally, examining the core material is essential; voids or gaps in the core can significantly compromise the strength and durability of the plywood. Furthermore, always inspect the edges of the panels for clean cuts and sealed surfaces to prevent moisture infiltration, which can lead to warping or deterioration over time.

When choosing plywood for your projects, it's crucial to avoid common mistakes that can lead to costly errors. One of the most frequent pitfalls is selecting the wrong grade of plywood. Misunderstanding the differences between grades can result in using material that either doesn't meet the aesthetic needs of your project or lacks the structural integrity required for safety and durability. Always consider the specific requirements of your project and consult grading charts to ensure you choose the appropriate type.

Additionally, many woodworkers overlook the importance of moisture content. Plywood that isn't properly dried or stored can warp over time, compromising the quality of your work. This is particularly critical when working on projects that require precision, such as fluted cabinets. To create these stylish designs, for instance, using moisture-stable plywood can ensure a smooth finish and elongated lifespan.

Avoiding these common mistakes will not only save you time and resources but will also elevate the overall quality of your woodworking endeavors.

When embarking on a project that requires finished plywood, understanding the budget implications is crucial. According to a report by the Freedonia Group, plywood demand is expected to increase, reaching roughly 22 billion square feet by 2025. This surge is partly driven by a rising preference for high-quality, sustainable materials in construction and furniture making. However, it's essential to recognize that premium finished plywood often comes with a higher price tag, with costs averaging between $45 and $90 per sheet depending on the quality and finish.

Investing in high-quality finished plywood not only enhances the aesthetic appeal of your project but also ensures durability and longevity. The Wood Products Council estimates that using top-grade plywood can improve structural integrity and reduce the need for frequent replacements, ultimately saving on long-term costs. For tailored outcomes, consider allocating at least 15% of your overall budget specifically for high-quality plywood, which might seem steep initially but can lead to significant savings down the line. Purchasing in bulk can also help mitigate costs, as distributors often offer discounts on larger orders, making quality plywood more accessible for various projects.

Signup our newsletter to get update information, promotion or insight.