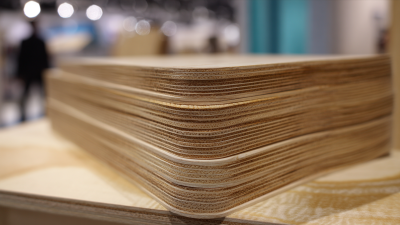

When embarking on a project that requires precise dimensions and quality materials, selecting the right option for birch ply cut to size can make all the difference. According to industry expert Mark Thompson, a seasoned woodworker and owner of Thompson Woodworks, "Choosing the right birch ply cut to size not only enhances the aesthetic appeal of your project but also ensures structural integrity." As more DIY enthusiasts and professionals turn to customized solutions, understanding the ins and outs of selecting the right birch ply becomes essential.

In today’s competitive market, the demand for birch ply cut to size has skyrocketed, leading to a variety of options that can be overwhelming. Selecting the right type requires knowledge of the material's properties, finishes, and potential uses. Mark Thompson emphasizes that a well-informed choice leads to superior results, stating, "Investing the time to choose wisely will pay off in the long run, both in terms of quality and satisfaction."

Exploring the essential tips for choosing birch ply cut to size will equip you with the knowledge necessary to make informed decisions, streamline your project workflow, and achieve the best possible outcomes. Whether you are crafting furniture, cabinetry, or other woodworking projects, the right birch ply will serve as the foundation for your creative vision.

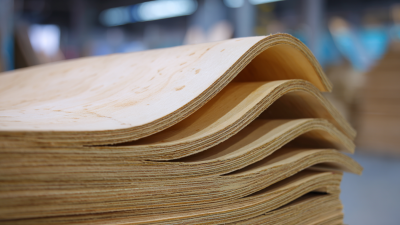

When choosing birch plywood for your projects, understanding the different types available and their best applications is crucial. Birch plywood is known for its durability and fine grain, making it an excellent choice for both structural and aesthetic purposes. The most common types include hardwood birch plywood, which is ideal for furniture making due to its strength and smooth surface, and marine-grade birch plywood, which is perfect for projects exposed to moisture, such as boat interiors or bathroom installations.

Additionally, there are various thicknesses and finishes available that can suit different requirements. For cabinetry and high-end finishes, select high-grade birch plywood, while for more rugged applications like shelving, standard grades will suffice. With Canberra's abundance of quality plywood suppliers, you can easily find the right type to meet your needs, ensuring that your project not only looks great but also stands the test of time.

| Type of Birch Plywood | Thickness | Best Applications | Price Range (Per Sheet) |

|---|---|---|---|

| Birch Plywood B/BB | 1/2 inch | Furniture, Cabinets | $30 - $50 |

| Birch Plywood BB/BB | 3/4 inch | Flooring, Shelving | $45 - $65 |

| Birch Plywood C/C | 5/8 inch | Construction, Subflooring | $25 - $40 |

| Marine Birch Plywood | 1/2 inch | Boat Building, Outdoor Projects | $70 - $100 |

| Birch Plywood Finishing Grade | 3/4 inch | Cabinetry, High-End Furniture | $60 - $90 |

When selecting birch plywood for custom cuts, understanding the grading system is crucial. Birch plywood is categorized into different grades, typically ranging from A to D.

Grade A represents the highest quality, featuring a smooth surface free of defects, making it perfect for visible applications.

Grade B has some minor imperfections but still maintains a high-quality appearance, while Grade C might include visible knots and other flaws, suitable for more structural applications where aesthetics are less critical. Knowing these grades helps in choosing the right plywood for your project’s specific needs.

Additionally, when considering birch plywood, factor in how the grading will affect the final outcome of your cuts. Higher-grade plywoods are usually more expensive, but they offer a superior finish that may save you time and resources in finishing processes.

Conversely, lower grades can be more economical but might require additional sanding and preparation to achieve a suitable look. Ultimately, understanding the nuances of birch plywood grading not only aids in making informed decisions but also ensures that your final project meets both functional and aesthetic standards.

When selecting birch plywood cut to size for your projects, it's crucial to consider several key factors. First and foremost, the thickness of the plywood plays a significant role in determining its strength and durability. Thicker panels are ideal for structural applications, while thinner sheets may be suitable for aesthetic purposes or lighter constructions. Additionally, the intended use of the plywood will influence the choice of thickness; for example, furniture making often requires more robust materials compared to decorative wall panels.

Another important factor to evaluate is the grade of the birch plywood. Plywood is graded based on its appearance and structural integrity, with higher grades featuring fewer blemishes and defects. If your project requires a polished finish, opting for a higher grade can enhance the overall aesthetic quality. Moreover, the size of the cut pieces should reflect your project's dimensions while minimizing waste. Carefully calculating the dimensions needed will not only save costs but also ensure a seamless fit during assembly. Balancing these factors will ultimately lead to a more successful and efficient use of birch plywood in your projects.

When selecting birch plywood for your projects, comparing it with other material options is essential. Birch plywood stands out for its durability, strength, and aesthetic appeal, making it an excellent choice for furniture, cabinetry, and crafts. Unlike MDF or particleboard, birch plywood possesses a natural wood grain that adds warmth and character to your creations. Its resistance to warping and splitting further enhances its usability in various applications, making it a preferred material for both professional and DIY projects.

When choosing birch plywood cut to size, consider the thickness required for your project. Thicker plywood can provide more strength, especially for structural elements like shelves or tables. Additionally, evaluate the veneer quality; higher-grade options offer a smoother finish and less chance of defects. If you need a versatile material that performs well in both functional and aesthetic aspects, birch plywood is a remarkable option to explore.

Ultimately, price point and application should be considered. While birch plywood may be more expensive than alternative materials, its longevity and visual appeal often justify the investment. By weighing these factors, you can make an informed decision that best suits your project needs.

When choosing birch plywood cut to size for your projects, maintaining quality during the custom cutting process is crucial. One way to ensure this is by selecting a trusted supplier who specializes in birch ply. A reputable supplier will have top-notch cutting equipment and experienced staff who understand how to minimize chipping and splintering, creating clean edges that enhance the final project appearance.

Another key tip is to pay attention to the thickness of the plywood when placing your order. Different projects may require various thicknesses for optimal strength and stability. Ensuring that your specifications are precise will help the cutter make accurate cuts without compromising the ply's integrity. Additionally, consider asking for samples before placing a large order. This allows you to assess the quality of the wood and the accuracy of the cuts, ensuring that you achieve the desired results in your projects.

Signup our newsletter to get update information, promotion or insight.