Birch plywood has become a quintessential material in the realm of DIY projects, offering strength, versatility, and a beautiful aesthetic that appeals to both amateur and professional builders alike. According to a recent report by the Plywood Manufacturers Association, the demand for high-quality plywood has seen a remarkable growth of 15% annually over the past five years, largely driven by the burgeoning DIY market. As more individuals seek to undertake their own home renovations and creative projects, the availability of "birch plywood cut to size" options has become increasingly vital.

Expert in the field of woodworking, Dr. Emily Hart, states, "The precision and quality of birch plywood cut to size can significantly elevate the outcome of any DIY endeavor." Her insights highlight the importance of selecting the right materials, as tailored plywood pieces ensure that projects not only meet design specifications but also leverage the inherent qualities of birch wood, such as durability and ease of sanding. In this context, diy enthusiasts are empowered to pursue their visions without compromising on material integrity, further solidifying birch plywood's reputation as a preferred choice for personalized woodworking solutions.

Birch plywood is a versatile and durable material made from multiple layers of birch veneer glued together, which provides strength and stability. One of the main reasons enthusiasts choose birch plywood for their DIY projects is its excellent workability. It can be easily cut, shaped, and stained, making it ideal for a variety of applications, from furniture making to decorative crafts. The fine grain and light color of birch also lend a natural beauty to the finished product, allowing for a clean and modern aesthetic.

Another significant advantage of birch plywood is its outstanding durability. It is less prone to warping compared to other types of plywood, which is essential for projects that demand a long-lasting and reliable material. This durability extends to both indoor and outdoor applications, making it a preferred choice for everything from cabinetry to shelving. Furthermore, birch plywood is an eco-friendly option since it utilizes natural materials and offers a sustainable alternative to solid wood, thereby contributing positively to the environment while elevating the quality of your DIY endeavors.

When selecting birch plywood for your DIY projects, it’s essential to understand the different types available, each with its own unique characteristics. The most common type is the Grade A Birch Plywood, which features a smooth surface and very few knots, making it ideal for applications where appearance is crucial. This high-quality plywood is often used in furniture, cabinetry, and decorative panels. Its consistent grain pattern and light color also allow for beautiful finishes, whether stain or paint.

Another notable type is the Grade B Birch Plywood, which may have a few more imperfections, like small knots and surface voids, but still offers a robust option for structural uses. This grade is perfect for projects where the back side won’t be visible, such as drawer sides or shelving. Additionally, there’s also Baltic Birch Plywood, known for its stability and thickness, offering layers of veneer that enhance durability. Its cross-banded construction minimizes warping, making it a favorite for intricate projects like laser cutting or laser engraving.

Each birch plywood type brings its advantages, allowing DIY enthusiasts to choose the best fit for their creative endeavors.

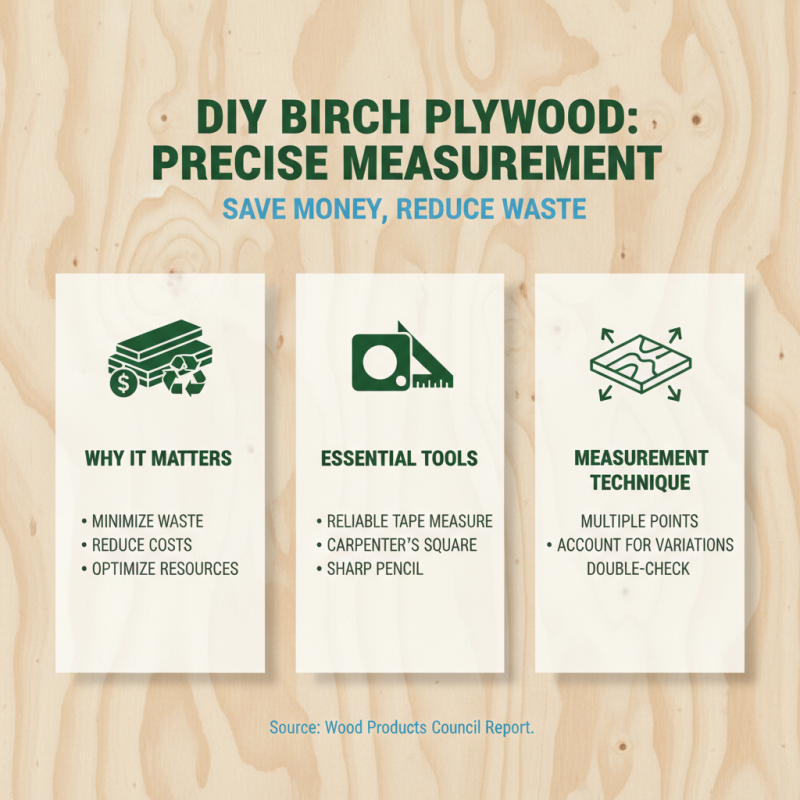

When embarking on a DIY project that involves birch plywood, accurate measurement and calculation are crucial to achieving the desired results. According to a report by the Wood Products Council, precise dimensions can minimize material waste and reduce costs significantly, allowing craftsmen to optimize their resources. To measure correctly, you should always use a reliable measuring tool, such as a tape measure or a carpenter's square, ensuring you take multiple measurements at different points to account for any variations in the material.

Once you have your measurements, calculating the right size for your plywood pieces can seem daunting. However, the National Plywood Association suggests employing simple formulas based on your project's design. For rectangular shapes, simply multiply the length by the width to find the area. If your project entails more complex shapes, use a grid method by breaking the shape into smaller rectangles and summing their areas. This approach not only enhances accuracy but also provides a clear vision of how much plywood you will need, ultimately facilitating smoother production processes.

When embarking on DIY projects, finding the right materials is crucial, particularly when it comes to birch plywood. Several retailers excel in offering cut to size birch plywood options, catering to both hobbyists and professionals. According to a report by the Wood Products Manufacturers Association, the demand for customized plywood solutions has surged by approximately 24% over the last five years, driving retailers to enhance their services and product offerings. This shift highlights the importance of local suppliers who provide personalized cutting services, ensuring that customers can obtain the exact dimensions needed for their projects.

Furthermore, a recent analysis from the Hardwood Plywood and Veneer Association indicates that birch plywood ranks among the top choices for cabinetry and furniture making due to its durability and aesthetic appeal. Retailers can often provide both standard sheets and personalized cutting services, allowing customers to take advantage of bulk purchasing while reducing waste. This trend not only helps in minimizing the environmental impact but also supports the growing preference for customized home decor solutions. By sourcing birch plywood from these top retailers, DIY enthusiasts can achieve a professional finish in their projects, tailored to their specific requirements.

When embarking on a DIY project, selecting the right materials is crucial for achieving quality results. Birch plywood stands out as a popular choice due to its durability and aesthetic appeal. According to the "2019 Wood Products Annual Market Review", the demand for plywood, particularly birch, is on the rise, with birch plywood typically accounting for over 12% of the total plywood consumption in North America. This versatile material is characterized by its fine grain and ability to withstand environmental stresses, making it ideal for furniture, cabinetry, and decorative projects.

Working with birch plywood requires some specific considerations to maximize its benefits. First, using the right tools is essential; a sharp, fine-tooth saw blade helps achieve clean cuts while minimizing splintering. Additionally, pre-drilling holes for screws can prevent splitting, especially at the edges of the plywood. Sanding the edges and surfaces with progressively finer grits enhances the smooth finish, which is especially important if you plan to stain or paint the plywood. Lastly, as highlighted in the "Plywood and Panel Market Analysis", maintaining a humidity-controlled environment during your project can ensure the plywood retains its shape and integrity, reducing the risk of warping over time. By paying attention to these tips, you can greatly enhance the quality and longevity of your birch plywood projects.

Signup our newsletter to get update information, promotion or insight.